The question “What is felt?” is among the topics that millions of people are curious about. Based on this interest, we have compiled this article to answer your questions. Enjoy reading.

Felt can be described as a practical material that is considered one of the oldest known textile products. Some types of felt are formed when animal fibers (such as sheep, mohair goat, llama, camel, rabbit, etc.) interlock with each other in an alkaline environment created by soap, water, and heat. Although the exact date of its first use is not clearly known, felt has a history dating back to ancient times. Due to its wide range of applications, it is still frequently preferred in many fields today. It is observed that felt is commonly used in souvenir production and in the works of many artists in recent times.

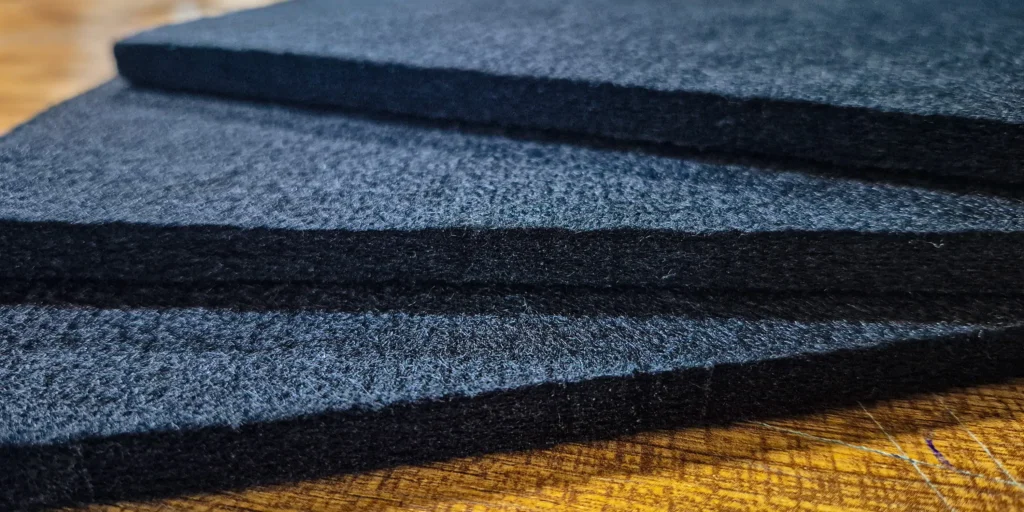

Basically, felt is formed by compressing fibers together without weaving them. It can be made from natural or synthetic fibers. Wet felting, a frequently preferred method, involves stimulating natural wool fibers through friction and moisture (usually water), allowing them to move at a 90-degree angle toward the source of friction and then retreat. It should be noted that many of the products around you are incorporated into daily use with the help of felt.

In addition to the above, only about 5% of the fibers are active at any given moment; however, the process is continuous, meaning different fiber clusters become active and then disengage during the ongoing process. Felt making predates spinning and weaving, and there are various cultural narratives about how it was invented.

What Is Felt?

From past to present, felt has been widely used in human life and is available on the market in various types made from different materials. Especially in the textile sector, felt holds an important place among fabrics used for various purposes. Therefore, it is quite natural for people to frequently ask the question: what is felt?

As mentioned above, felt can be described as a type of fabric made from fibers. Felt is produced by processing fibers obtained from the wool of animals—primarily sheep—or from polyester.

Unlike other fabrics produced by weaving, felt is manufactured through compression. The main reason for this is that compression allows fibers to bond tightly with each other, increasing the durability of the fabric. In some cases, felt is also blended with other yarns such as silk or acrylic to give it additional properties.

Felt is the oldest type of fabric used by humans and has not lost its value over the years. Some sources date the origin of felt back 5,000 to 6,500 years, indicating that it may have emerged in different regions at different times or spread through trade.

In general, Central Asia is considered the homeland of felt. The prevalence of livestock farming in the region and the discovery of felt carpets and materials during excavations support this view.

In its earliest days, felt was produced by hand through compression. After the Industrial Revolution, production shifted to machines, accelerating manufacturing. The widespread use of felt coincided with this period, as faster and higher-quality production enabled felt to be manufactured at lower costs while maintaining high quality.

Felt Prices

With the widespread use of felt, felt prices have become another topic of interest. There are many factors that determine felt prices, with quality being the most important.

As felt quality increases, prices inevitably rise. Usage performance is directly linked to quality, making it the primary determinant of price.

Additionally, increased demand for felt has led to a rise in the number of felt manufacturers, causing price variability. Not all felt products are of equal quality, and higher-quality felts naturally command higher prices.

Felt thickness also affects pricing. Thicker felts require more raw material and labor, making them more expensive than thinner felts. As in all industries, products requiring more workmanship tend to be higher in both quality and price. Brand recognition also plays a role—products from well-known brands are generally more expensive.

The quantity of felt purchased also affects pricing. Wholesale purchases typically offer more favorable pricing compared to retail. As order quantities increase, unit prices decrease, making wholesale purchasing more cost-effective.

To ensure long-term usability and satisfaction, buyers should prioritize quality over price. Choosing cheaper felt may lead to higher costs in the long run. Therefore, identifying high-quality felt that meets expectations is essential, after which reasonably priced options among high-quality products can be selected.

Felt Production

Although felt production dates back to ancient times, it has evolved alongside technological advancements. After the Industrial Revolution, significant progress was made in felt manufacturing.

Before industrialization, felt was produced by wetting and compressing wool fibers by hand. Today, with increased mechanization, more innovative methods are used.

Modern felt production still relies on fiber compression. Wool fibers are placed into cylindrical drums filled with needles to form a cohesive structure. The material is then carded until fiber distribution becomes uniform. The resulting layers are combined and compressed, exposed to heat and moisture to enhance bonding. Finally, rollers are used to smooth the surface.

Following these processes, felts suitable for various industries—especially textiles—are produced. Due to its extensive applications, many types of felt are available on the market.

Types of Felt

Although felt may seem like a single product, there are many types available. Common felt types include:

- Wool Felt: The most commonly used felt, made from sheep wool and other animal fibers. It is the earliest form of felt produced by humans.

- Fur Felt: Used mainly in hats and garments, made from animal fur such as beaver. Its use is limited due to animal rights concerns.

- Acrylic Felt: Similar to wool felt but flammable and may cause skin irritation. Despite disadvantages, it is widely used due to low production costs.

- Rayon Felt: Also known as artificial silk felt. It can be shaped with various insulators but is not biodegradable.

- Pressed Felt: Produced by bonding wool fibers using water, steam, and pressure.

- Needle Felt: Common in arts and crafts, created by mechanically interlocking fibers with needles.

- Woven Felt: Produced by applying heat, water, and pressure to woven materials.

Felt Fabric

With its deep-rooted history, felt fabric has been used for various purposes over time. Its functional benefits have led to expanding applications.

Felt is used in textiles and many industrial sectors. In textiles, it increases product durability and is used both directly in garments and for decorative elements. It also plays a significant role in arts and crafts.

Due to its insulating properties, felt is used as floor covering in areas with electrical currents. It is also used as padding under furniture to prevent slipping. Additionally, felt is commonly found in vehicle interiors and floors to reduce vibration and noise.

Areas of Use of Felt

The applications of felt continue to expand with technological advancements. Different felts serve different purposes and are categorized accordingly:

- Thin Felt: Used in textiles, shoe interiors, hats, coats, and decorative applications.

- Thick Felt: Preferred in industrial sectors, especially automotive, for insulation and flooring.

- Roll Felt: Thin or thick felts produced in roll form, used across industries.

- Adhesive Felt: Used in crafts and furniture to prevent slipping.

- Interlining (Punteriz) Felt: Widely used in the textile industry to reinforce seams.

Advantages of Felt

Felt has been used for thousands of years due to its durability. While many fabrics wear out over time, felt shows minimal wear.

Its ease of processing makes felt one of the most preferred textile materials. It is antibacterial, non-allergenic, hygienic, radiation-resistant, cost-effective, and long-lasting—making it ideal for children and sensitive users.

Where to Buy Felt?

With increased felt usage, many suppliers have entered the market. Choosing the right supplier is crucial for quality and longevity.

Keçe Dünyası has been filling a significant gap in the sector since 2010, offering wholesale and retail felt products manufactured with the latest technologies. Customer satisfaction and product quality are our priorities.

For both retail and wholesale purchases, Keçe Dünyası provides a wide range of felt products in various colors, sizes, and thicknesses.

Wholesale Felt Purchasing

Wholesale felt purchasing is preferred for cost efficiency and quality. Many industries, especially textiles, rely on bulk purchasing.

Buying in bulk reduces costs and ensures continuity. Keçe Dünyası supports customers with flexible quantities and reliable supply.

Working with a professional supplier increases satisfaction. Keçe Dünyası is always ready to answer your questions and meet your felt needs.