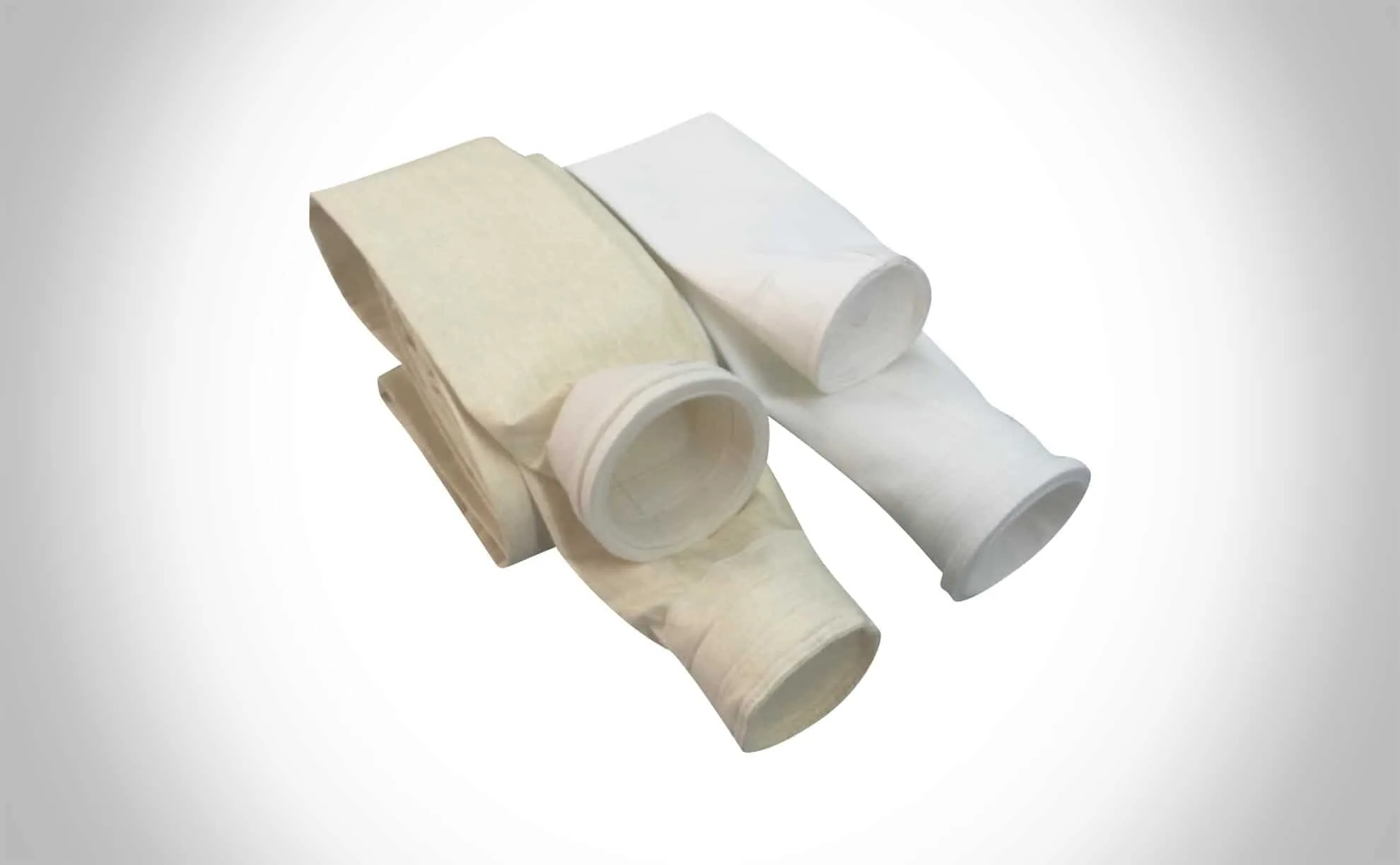

Product Images

Keçe Dünyası Industrial Filter Felt – High-Efficiency Filtration That Extends the Life of Your Machinery

In manufacturing facilities, air quality and machine health are fundamental pillars of productivity. Unfiltered air in industrial environments leads to abrasion, equipment failure, and non-compliance with regulations—resulting in significant costs.

Keçe Dünyası industrial filter felt collection is a high-performance nonwoven technical filtration solution specifically designed to eliminate these risks. These felts effectively capture airborne dust, micro-particles, fumes, chemical pollutants, and metal shavings—protecting employee health while significantly extending the service life of your valuable and sensitive production equipment.

Our filter felts are produced using polyester (PET), polypropylene (PP) with high chemical resistance, or specially engineered synthetic fibers for specific temperature conditions. As a result, each product delivers critical technical performance such as high dust-holding capacity, optimized air permeability, and high temperature resistance up to 160°C.

Manufactured using needle-punch and thermal fixation techniques, these felts maintain structural stability even under continuous airflow and pressure, ensuring reliable particle retention without leakage.

They are widely used in dust collection systems (bag filters, cartridge filters), automotive paint booths, HVAC units, and chemical processing equipment. From our Istanbul-based production facility, we provide fast and uninterrupted industrial filter felt supply to facilities across all industrial regions, including Istanbul, Ankara, Izmir, Bursa, and Kocaeli.

Enhance your filtration systems with Keçe Dünyası quality for higher efficiency, reduced downtime, and full regulatory compliance.

Why Choose Keçe Dünyası Technical Filtration Solutions?

Selecting the right filter felt not only ensures regulatory compliance but also directly reduces operating costs and improves production quality.

- Maximum Machine Protection and Operational Efficiency:

High-density structure with adjustable pore size captures harmful dust, chips, and sub-micron contaminants—extending the lifespan of production equipment. Clean airflow reduces energy consumption and minimizes breakdown risks. - High Temperature and Chemical Resistance:

We offer filter felts resistant to temperatures between 120°C and 160°C for process lines, ovens, and hot air circulation systems. For chemically aggressive environments, our PP-based solutions provide enhanced resistance against chemical degradation. - Guaranteed Quality with Precision Filtration Classes:

Available filtration classes from G3 to F7 (compliant with ASHRAE / ISO standards) ensure project-specific air cleanliness—from coarse pre-filters (G3/G4) to fine particle filtration required for paint booths (M5/F7). - Optimized Airflow and Energy Efficiency:

Our production technology precisely balances air permeability and density without compromising filtration quality. This optimization reduces fan load, improves energy efficiency, and lowers operational costs. - Easy Integration and Custom Cutting:

Filter felts are supplied in large rolls or custom-cut sheets according to your specifications. This flexibility enables fast integration into modular filter systems, bag filters, and cartridge filter surfaces. - Nationwide Uninterrupted Supply Across Türkiye:

To ensure continuous production and regulatory compliance, we provide fast and reliable shipment of industrial filter felts from Istanbul to all industrial facilities across Türkiye. Our strong stock availability and high-capacity manufacturing keep your operations running without interruption.

Industrial Filter Felt – Technical Specifications and Application Details

Detailed technical parameters to help you select the right solution for your process line:

- Material Composition: Polyester (PET), Polypropylene (PP), Chemical-Resistant Technical Fibers

- Weight Range: 100 g/m² – 800 g/m²

- Thickness Range: 3 mm – 30 mm

- Filtration Class: G3, G4, M5, M6, F7 (International standards compliant)

- Maximum Operating Temperature: 120°C – 160°C (depending on material type)

- Manufacturing Method: Needle-punched & Thermal Fixation

- Dust Holding Capacity: High, industrial-grade performance

- Air Permeability: Adjustable density to suit different process requirements

- Application Areas: Dust collection systems, HVAC units, paint booths, industrial process lines

- GEO Information: Co

Frequently Asked Questions

Industrial filter felt is a specialized technical filtration material used in manufacturing facilities and industrial ventilation systems to capture dust, particles, and chemical contaminants. Its importance lies in protecting internal machine components, minimizing downtime caused by malfunctions, ensuring compliance with occupational safety regulations, and safeguarding employee health.

Industrial filter felts are commonly manufactured from Polyester (PET) for mechanical strength and cost efficiency, Polypropylene (PP) for chemical resistance and moisture tolerance, or specially engineered technical fiber blends for high-temperature applications. PET-based felts offer the most balanced solution for general industrial use.

For dust collection machines, G4 (Coarse) or M5 (Medium) class filter felt is generally recommended; for HVAC systems, M5/M6 is preferred for energy efficiency and comfort; and for paint booths, M6/F7 class high-performance filter felt is recommended to trap paint particles.

High-temperature resistance indicates that the filter felt maintains its structure and filtration performance without shrinking, melting, or degrading at temperatures between 120°C and 160°C. This property is critical for industries operating furnaces, drying lines, hot air circulation systems, and metal processing equipment.

Keçe Dünyası supplies industrial filter felts both in high-length rolls for large-scale manufacturers and in custom-cut sheet (plate) form for small and medium-sized workshops requiring ready-to-install solutions.

Service life depends on particulate concentration, airflow velocity, and the selected felt’s weight and density. The ideal replacement time is determined when accumulated contaminants cause a critical increase in airflow resistance, reducing system efficiency.

Industrial filter felts efficiently capture micron-level dust, pollen, metal shavings, paint particles, industrial fumes, soot, and harmful chemical pollutants, according to their designated filtration class.

Yes. For sensitive processes in chemical, food, and pharmaceutical industries, polypropylene (PP)-based chemical-resistant filter felts can be produced, offering enhanced resistance to acids, alkalis, and solvents.

The primary function of filter felt is particulate filtration. However, due to its thick (3 mm – 30 mm) and dense structure, it can partially absorb industrial noise and contribute indirectly to low-level acoustic insulation.

With sustainability in mind, we offer industrial filter felts made from recycled PET fibers for environmentally conscious manufacturers. These solutions reduce environmental impact without compromising filtration performance.