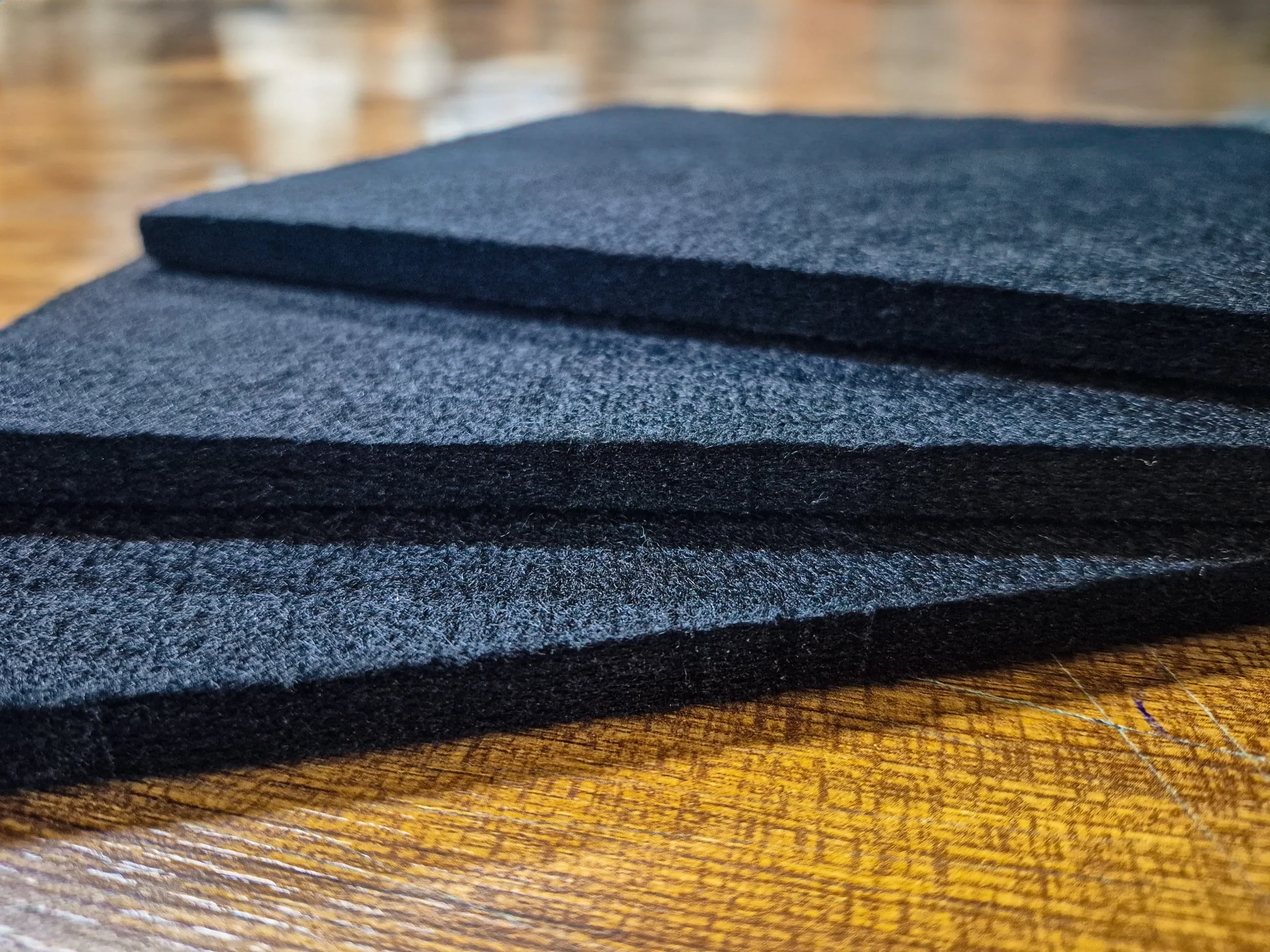

Product Images

Keçe Dünyası Mattress Felt – A Core Support Material That Enhances Sleep Quality and Product Longevity

The quality of a mattress lies in its unseen inner layers. Mattress felt is one of the most critical nonwoven materials used in mattress manufacturing for comfort, structural durability, and filling purposes, forming the backbone of the mattress. The technical felts we produce ensure that mattresses retain their shape for years and provide consistent, long-term support to the user.

Whether you are looking for felt for spring systems (Bonnell springs, pocket springs) or fully foam-based mattresses, the right felt perfectly absorbs spring impact, reduces spring noise, and significantly extends the overall lifespan of the mattress.

Types of Felt Used in the Mattress Industry:

- Needle Punch Felt (Firm Felt)

Produced using a high-density needle-punch technique. Its firm, strong, and durable structure makes it ideal as a support layer above or below spring systems, providing firmness and shape stability to the mattress. - Thermobond Felt (Soft Felt)

Thermally bonded with a softer, comfort-enhancing structure. Commonly used as an intermediate filling layer in mattress toppers and foam mattresses.

With thickness options ranging from 3 mm to 20 mm and densities from 300 gsm to 2000 gsm, we offer mattress manufacturers solutions tailored to their desired level of firmness and durability. In addition, anti-bacterial and flame-retardant (FR) options are available to ensure compliance with industry standards. From our production center in Istanbul, we provide uninterrupted nationwide supply to mattress manufacturers across Turkey.

Why Choose Keçe Dünyası Mattress Felt?

- Spring Protection & Noise Insulation

In spring mattresses, the felt layer significantly reduces noise and vibration caused by spring movement, creating a quieter and higher-quality sleep environment. - Resistance to Sagging & Deformation

Our high-quality needle-punched, high-GSM felts show excellent resistance to continuous pressure, maintaining mattress form over long-term use. - Variety & Flexibility

With both Thermobond (soft) and Needle Punch (firm) options, you can easily select the required softness or firmness—whether for a luxury comfort topper or an extra-firm medical mattress. - Sustainability

Upon request, we use recycled PET fibers, contributing to environmentally friendly and sustainable production solutions. - Custom Size Production

We offer custom cutting and roll supply for mattress widths ranging from 120 cm to 240 cm.

Mattress Felt – Technical Specifications & Application Areas

- Material: Polyester (PET), PP, Recycled PET, or blended fibers

- Production Method: Needle punch or Thermobond (thermal bonding)

- Thickness Options: 3 mm to 20 mm (wide range)

- Weight / Density: 300 g/m² – 2000 g/m² (determines density and durability)

- Firmness: Firm/rigid options for spring support; soft/medium options for filling

- Width: Custom production from 120 cm to 240 cm

- Special Treatments: Anti-bacterial and FR (flame-retardant) options

- Applications: Spring and foam mattresses, mattress toppers, bed bases, and furniture fillings

- Logistics Info: Fast delivery from our Istanbul production center to mattress and furniture manufacturers across Turkey

Frequently Asked Questions

Yes. From our production facility in Istanbul, we provide fast and reliable delivery to all mattress production regions across Turkey. The wholesale supply process is custom-planned based on your required thickness, weight (GSM), and firmness parameters.

Yes. High-density felts (1000 gsm and above) are typically used as support layers above spring systems and in areas exposed to the highest load, to enhance durability.

Yes. Our production line supports custom cutting according to mattress widths ranging from 120 cm to 240 cm, tailored to your specific model.

Yes. We offer FR (flame-retardant) felts that comply with international safety standards, helping your products meet required regulations.

Mattress felt is a special nonwoven material used for support, filling, and durability in mattress production. Its primary function is to protect springs, reinforce mattress structure, and enhance comfort.

It is suitable for almost all mattress types, including spring, foam, hybrid, and medical mattresses.

Thermobond (heat-bonded) felt is softer and more comfort-oriented, while needle punch felt has a firmer, harder, and more durable structure.

Firm (needle-punched) felts are preferred for spring support layers. Softer (thermobond) felts are selected for comfort surfaces and mattress toppers.

Yes. The felt layer significantly absorbs spring impact and noise, directly contributing to improved sleep quality.

Yes. Mattress felts are also widely used as support and filling materials in sofa and couch manufacturing.

Felt density is one of the most critical factors determining durability, resistance to deformation, and overall product lifespan. Higher density means longer service life.

High-quality needle-punched felt maintains its form for many years when properly supported and does not sag.

Yes. Due to their soft structure, thermobond felts are ideal as comfort-enhancing intermediate layers in mattress topper production.

Yes. Antibacterial treatments can be applied upon request, ensuring a hygienic structure.

Yes. With a strong focus on sustainability, we offer production using recycled (Recycle) PET fibers.

Yes. It is used as internal lining and filling felt in bed bases, improving both insulation and durability.

No. Mattress felts are not washable. However, since they are used inside a closed mattress structure, they require no maintenance.

Generally, thicknesses of 5–12 mm are sufficient for spring support, and 3–8 mm for interlayer padding and comfort surfaces.

Yes. Mattress felts are resistant to heat used in industrial mattress production, including adhesive curing and thermal oven processes.